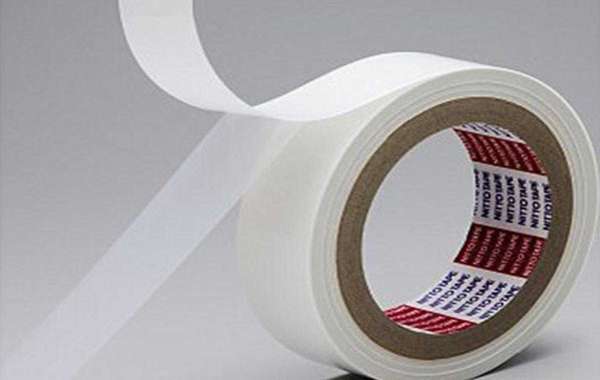

Double sided adhesive tapes have revolutionized manufacturing processes, offering efficient and precise bonding solutions across a multitude of industries. This article explores how these tapes contribute to double sided adhesive tape manufacturer efficiency, precision, and reliability in modern manufacturing.

Role in Manufacturing Efficiency

Assembly Processes:

- Automotive Industry: Bonding of interior and exterior components such as trim, emblems, and panels, reducing assembly time and enhancing vehicle aesthetics.

- Electronics: Mounting of displays, touchscreens, and circuit boards in consumer electronics and industrial equipment, streamlining production processes.

Construction and Building:

- Architectural Applications: Installation of mirrors, glass panels, and signage without drilling or visible fasteners, maintaining surface integrity and aesthetic appeal.

- Insulation and Sealing: Bonding of insulation materials and sealing joints for energy efficiency and weather resistance in building construction.

Medical and Healthcare:

- Medical Devices: Securing medical components, electrodes, and sensors in diagnostic and therapeutic equipment, ensuring reliability and patient safety.

- Wound Care: Attaching wound dressings and surgical drapes securely with hypoallergenic tapes, promoting healing and comfort.

Advantages of Double Sided Adhesive Tapes

- Versatility: Bonds to a wide range of substrates including metals, plastics, glass, and fabrics, accommodating diverse application needs.

- Convenience: Simplifies assembly processes by eliminating the need for mechanical fasteners, reducing labor costs and assembly time.

- Durability: Provides strong adhesion under various environmental conditions such as temperature fluctuations and moisture exposure.

Precision and Reliability in Bonding

- Uniform Stress Distribution: Conforms to irregular surfaces and distributes stress evenly, enhancing bonding strength and longevity.

- Clean Application: Creates seamless bonds without visible fasteners, improving product aesthetics and functionality.

- Customization: Available in various widths, thicknesses, and forms (rolls, sheets, die-cuts) to suit specific assembly requirements and application scenarios.

Future Trends and Innovations

- Advanced Materials: Development of adhesives with enhanced properties such as high temperature resistance, chemical compatibility, and environmental sustainability.

- Smart Integration: Integration of sensors or RFID tags into tapes for real-time monitoring and data collection in smart devices and structures.

- Bio-Inspired Adhesives: Exploration of adhesives inspired by natural phenomena for improved performance in challenging environments.

Conclusion

Double sided adhesive tapes continue to play a critical role in enhancing efficiency, precision, and reliability across diverse manufacturing sectors. As technology advances and customer demands evolve, these tapes are expected to drive further innovation, supporting sustainable practices and meeting the increasing need for versatile bonding solutions in modern manufacturing environments. With their ability to streamline processes, improve product performance, and ensure quality assembly, double sided adhesive tapes remain indispensable tools for achieving operational excellence and competitive advantage in the global marketplace.