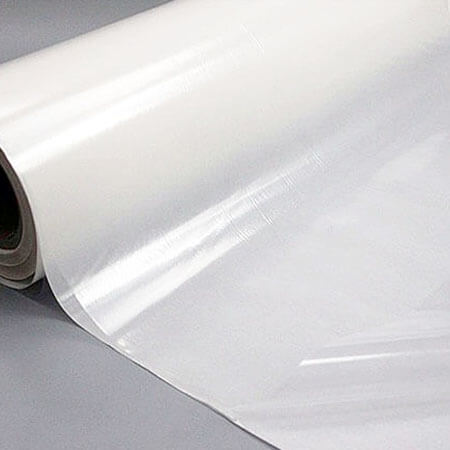

The melting of hot melt adhesive particles results in the formation of the thermoplastic material known as hot melt adhesive film. The film that was produced is smooth and has the appearance of a double-sided adhesive. It adheres well to a variety of fabrics, including cotton, polyester, and blended materials. It is resistant to both heat and cold and can be fashioned into any desired form or dimension. In circumstances where a high level of strength is essential, ELPHAN NT is the material of choice. Film made of thermoplastic polyurethane (TPU) has superior elasticity and resistance to cold temperatures.

There are a few different grades of hot melt adhesive films available, and some of these grades include polyolefins, polyester, and polyurethane. The thermoplastic adhesive can withstand high and low temperatures without breaking down, making it ideal for use in food packaging. In addition to this, hot melts have a low impact on the surrounding ecosystem, and they can be applied in a wide variety of contexts. In addition, these flexible films can be utilized for a wide range of applications, including, but not limited to, the sealing of bags and boxes, as well as the adhering of paper and fabric to one another.

A plastic film whose melting point falls somewhere in the range of one and three hundred degrees is referred to as a hot melt adhesive film. TPU is an excellent choice for a wide variety of projects thanks to the high degree of flexibility it possesses. Because of its resistance to ultraviolet light, its longevity, and the ease with which it can be processed, it is a favorite among manufacturers of textiles and apparel. It is unavoidable that it will be utilized in the clothing manufacturing industry. On the other hand, there are some restrictions. If you choose your hot melt adhesive film carefully, it will not only save you time and money but also keep your garments looking great over time.

It is not affected by water, extreme high or low temperatures, or the cold. In addition to that, it is very breathable and gentle to the touch. This particular type of hot melt adhesive film is a relatively new product on the market in spite of the numerous advantages that it offers. It is a film made of thermoplastic material that has great qualities for use in clothing. An aqueous polymer dispersion is a specific kind of this material that can be found. Because the hot melt is liquid, it must be heated before it can perform its function as an adhesive.

Thermoplastic materials can be solid when they are supplied, and one such material is the hot melt adhesive film. When subjected to heat, the film will morph into a liquid state. Fabrics, foam, and even some types of foam can be bonded together using this type of material. Because of its low cost and the fact that it is not harmful to the environment, it is an excellent choice for a variety of applications. If you need to bond different materials together, one of the best options is to use hot melt adhesive film.

The hot melt adhesive film is a thermoplastic film that is flexible and can be heated and reheated multiple times to bond different materials. It is an excellent material for many different applications, including clothing, due to its properties. It can withstand high temperatures and is an excellent choice for use in the textile industry. The primary output of a TPU hot melt adhesive film is a thermoplastic material that is of superior quality and is reversible. It is manufactured using the most advanced meltblown machine, which eliminates the use of unnecessary fillers and enhances the product's resistance to washing and odor.

The use of polyurethane hot melt adhesive film is recommended for a variety of different projects. Its high level of adhesion is beneficial for a wide variety of materials in a variety of applications. The water resistance of the film is exceptional, and it features a double-sided adhesive coating. It takes very little time to cure and has no discernible odor. Because of this, it is perfect for sewing and various other projects. Try using TPU hot melt film as an adhesive for fabrics if you are in the market for one. It is advantageous in many ways.

There is yet another variety ofhot melt adhesive film known as TPU hot melt adhesive film. It is a material that can adhere to a wide variety of substrates and has two distinct sides. In contrast, hot melt film is an excellent choice for applications that require a soft hand, and this product is especially effective for fabric lamination. It is recommended that you make use of a thermoset adhesive if the application you are working on calls for a high level of adhesion. TPU films, in contrast to their thermoplastic counterparts, are also resistant to the effects of chemicals.