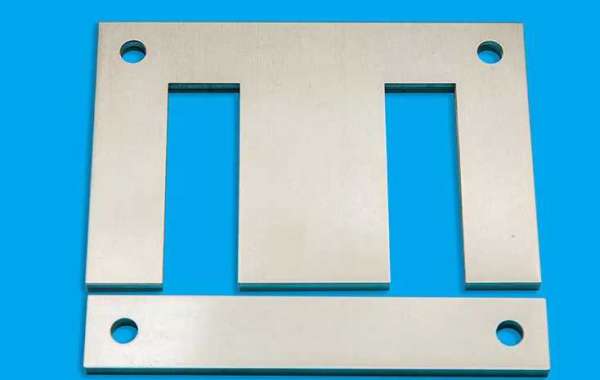

When it comes to electric motors, silicon steel sheets play a vital role. Silicon steel is a type of steel that contains a small amount of silicon. It’s this silicon that helps to improve the magnetic properties of the steel. This is important because electric motors rely on magnets to generate the electromagnetic field that creates rotation. The more powerful the magnets, the more efficient the motor will be. In this blog post, we will explore the role of silicon steel sheets in electric motors. We will discuss how they work and why they are essential for creating high-performance motors.

What are the properties of silicon steel that make it ideal for use in motors?

Due to its high silicon content, silicon steel has very low levels of carbon and other impurities. This results in a very strong and durable metal that is ideal for use in electromagnets and motors. The high strength of silicon steel means that it can withstand the large magnetic forces generated by electromagnets without warping or breaking. Additionally, the low levels of impurities make it an excellent conductor of electricity, which is essential for efficient operation of motors.

What are the benefits of using silicon steel in motors?

As the name suggests, silicon steel is steel that has been alloyed with silicon. In motors, the addition of silicon to steel improves the electrical resistance of the metal, which in turn reduces energy losses in the motor. This makes silicon steel an ideal material for use in electric motors, as it can improve the efficiency of the motor by reducing energy losses.

In addition to its improved electrical properties, silicon steel also has a higher melting point than regular steel. This makes it ideal for use in high-temperature environments, such as in motors that are used in automotive applications.

Overall, silicon steel is an ideal material for use in electric motors due to its improved electrical and thermal properties. Silicon steel can help to improve the efficiency of motors by reducing energy losses and by allowing them to operate in high-temperature environments.

Are there any drawbacks to using silicon steel in motors?

While silicon steel is an excellent material for use in motors, there are a few potential drawbacks to consider. One issue is that silicon steel can be brittle, meaning it can break or crack under high stress or impact. Additionally, silicon steel is a poor conductor of electricity, which can limit its usefulness in certain applications.