PSHMA: Its Qualities and Traits

PSHMA's ability to form strong bonds with relatively little effort and heat is arguably the most important quality it possesses

In addition to this, it has a very high resistance to solvents and a reasonable resistance to the effects of UV radiation

In addition to this, it creates sturdy bonds that are capable of withstanding vibration or movement without becoming brittle or falling apart over the course of time

Because of its quick setting capabilities, it is an excellent option for high-speed assembly lines, where efficiency is of the utmost importance

The term "pressure-sensitive hot melt adhesive" (PSHMA) refers to a type of adhesive that forms strong bonds between two surfaces through the application of pressure rather than heat. Businesses that are looking to streamline their production processes while still maintaining high-quality standards in their products may find it to be an attractive option due to the ease with which it can be used as well as its durability.

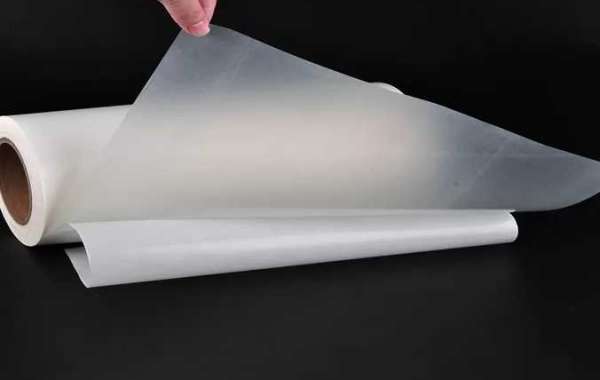

Hot Melt Pressure-Sensitive Adhesive Film, Product Number 6791

PSHMA, which stands for pressure-sensitive hot tpu hot melt adhesive film adhesive, is a type of adhesive that forms a bond that is safe and dependable. It is an excellent choice for uses that call for an immediate and sturdy bond that is also capable of withstanding the passage of time. Let's take a look at some of the benefits that come with this.

PSHMA offers a solution that is both quick and easy to use for all of your application requirements. Because of this, you will be able to move on to other tasks in a more timely manner as opposed to waiting for the glue to dry, which will ultimately save your company both time and money. In addition, because PSHMA cures so rapidly, it cuts down on the amount of product that is wasted as a result of errors in curing or improper application. In addition to this, PSHMA has a high resistance to both heat and moisture, which indicates that it is able to withstand a variety of environmental conditions without the bond's integrity being compromised over time. You can save even more money in the long run if you minimize the amount of product that is wasted as a result of improper usage or improper curing. This is because you won't have to buy replacements for the goods that would have been thrown away because of the ineffectiveness of the bonding procedures.

It has quick setting times, which results in quicker turnaround times, and reduced product waste due to fewer curing errors or improper usage; its durable bond ensures that your products will last longer; and its cost-effectiveness makes it an affordable option overall. PSHMA is an excellent choice when searching for an effective bonding solution that is tailored to the requirements of your company because it combines all of these benefits into a single adhesive solution.

How to Determine Which Temperature-Sensitive Pressure-Sensitive Hot Melt Adhesive Is Best For Your Project

One variety of adhesive that is put to use in a wide variety of commercial endeavors is known as pressure-sensitive hot tpu hot melt adhesive film adhesive. Nevertheless, selecting the appropriate pressure-sensitive hot tpu hot melt adhesive film adhesive for your project can be a challenging endeavor. In this article, we will discuss how to determine which pressure-sensitive hot tpu hot melt adhesive film adhesive is best suited for the project you are working on. Which kinds of materials are you going to be bonding together? Do you anticipate the need for an adhesive that is resistant to high temperatures or certain chemicals? Do you require an adhesive that has a high tack or one that has a low tack?

It is also a good idea to consult an experienced professional who is knowledgeable in the application of pressure-sensitive hot adhesives. It is essential to take into account all aspects of your project before making a final decision in order to get exactly what you require at a price that is in line with other options. Keeping these pointers in mind should make the search for the ideal PSHM a lot less difficult.

How to Purchase Pressure-Sensitive Hot Melt Adhesive: a Buyer's Guide

Hot-melt pressure-sensitive adhesive tpu hot melt adhesive film (product number 6793);

PSA stands for pressure-sensitive hot adhesive, which is a type of high-performance adhesive that has a variety of uses in the commercial and industrial sectors. When shopping for PSA, it is important to take into consideration the kind of application you will be using the adhesive for. This will allow you to choose the product that is most suited to your requirements. The following are some helpful hints regarding the purchase and application of pressure-sensitive hot melt adhesives.

Various Forms of Adhesives

When it comes to choosing a PSA adhesive, you have a few different options to pick from. For instance, if you need an adhesive that has a high resistance to heat or one that can function well in wet areas, you might have to go with a specialty adhesive.

Considerations Regarding the Application

After you have determined which PSA adhesive is most suitable for the job at hand, the next step is to consider how the adhesive will be applied. Roll coating and spray coating are the two methods that are used the most frequently when applying pressure-sensitive adhesives.

It is important to choose the right method based on the specific requirements of your application. For example, if you are bonding thick materials together, roll coating might not provide enough coverage, whereas spray coating might waste material if only thin layers of bond strength are required.